In today’s global market, counterfeiting is a significant challenge for brands, especially in industries such as pharmaceuticals, luxury goods, and electronics. To combat this, companies are increasingly relying on advanced anti-counterfeiting technologies to protect their products. Two prominent solutions in the field of anti-forgery printing are ultraviolet (UV) anti-forgery printing ink and laser anti-counterfeiting ink. While both offer enhanced security features, each has its distinct applications and advantages. In this article, we will compare these two technologies and help businesses choose the best anti-counterfeiting solution for their needs.

1. Understanding Ultraviolet Anti-Counterfeiting Ink

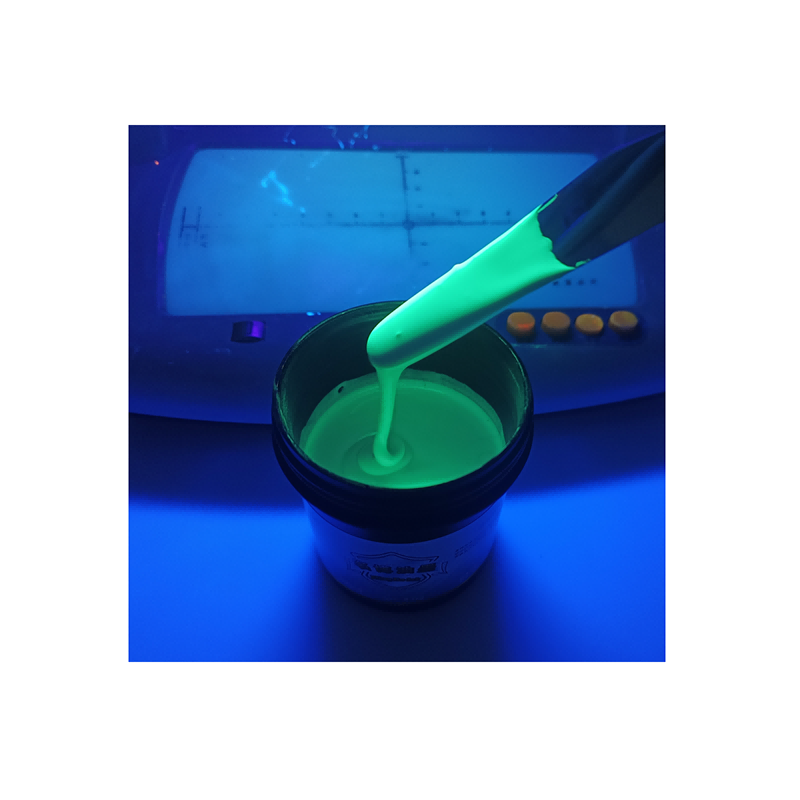

Ultraviolet anti-forgery printing ink is a specialized ink that is visible only under UV light. This ink is commonly used for printing serial numbers, security logos, and other sensitive information on products or packaging. The primary advantage of UV ink lies in its ability to remain hidden from the naked eye, making it nearly impossible to detect without the proper UV light source. This feature enhances security by ensuring that counterfeiters cannot easily replicate the marks.

Ultraviolet anti-forgery printing ink works on various surfaces, such as paper, plastic, and metal. This makes it highly versatile for a wide range of products. It is commonly used in documents like tickets and certificates. Additionally, the ink is applied in packaging, pharmaceuticals, and high-value consumer goods.

Advantages of UV Ink:

1.1 Invisible to the naked eye, enhancing security.

1.2 Cost-effective and easy to apply to various materials.

1.3 Customizable to feature unique markers, logos, or codes.

2. Exploring Laser Anti-Counterfeiting Ink

Laser anti-counterfeiting ink creates permanent, tamper-proof marks. The ink is applied using a laser engraving process, which leaves intricate patterns or codes. These marks are visible without special lighting. Unlike UV ink, laser-engraved marks are physically etched onto the surface. As a result, they are more durable and harder to replicate.

Laser marking technology is particularly suitable for applications requiring high precision, such as electronics, automotive parts, and high-value luxury items. The permanence of the marks makes laser ink a preferred choice. It is ideal for products exposed to rough handling or harsh environmental conditions. This durability ensures the ink remains intact under challenging circumstances. As a result, laser ink provides long-lasting and reliable markings.

Advantages of Laser Ink:

2.1 Permanent and tamper-proof markings.

2.2 Highly durable, even under extreme conditions.

2.3 Ideal for high-precision applications.

3. Key Differences Between UV Ink and Laser Ink

While both UV anti-counterfeiting ink and laser anti-counterfeiting ink provide robust security features, they differ significantly in terms of application and security strength.

3.1 Visibility: UV anti-forgery printing ink is invisible to the naked eye and requires special UV light to view, while laser markings are permanent and visible without any special equipment.

3.2 Durability: Laser ink creates permanent marks that cannot be altered or erased, while UV ink can be compromised if exposed to certain conditions or improperly applied.

3.3 Cost: UV anti-forgery printing ink is generally more cost-effective for large-scale printing, making it an ideal choice for mass-produced products. In contrast, laser engraving involves more specialized equipment and may be more expensive.

3.4 Applications: UV ink is best for items that require hidden markings, such as packaging or labels. Laser ink is suitable for more permanent applications, such as engraved serial numbers on high-value goods.

4. Choosing the Right Anti-Counterfeiting Solution

The choice between ultraviolet anti-counterfeiting ink and laser anti-counterfeiting ink largely depends on the specific needs of your business and the nature of the product you’re trying to protect. Here are some factors to consider:

4.1 For high-volume, cost-effective anti-counterfeiting: UV ink is a great option, especially for items that will be sold in large quantities. It offers invisible security marks that are difficult for counterfeiters to detect.

4.2 For permanent, high-security markings: If you need marks that will stand the test of time, laser engraving might be the better option. It provides a highly durable and tamper-proof solution for products that require long-term security.

5. Applications in Different Industries

5.1 Pharmaceuticals: Both UV ink and laser ink are used extensively in the pharmaceutical industry to prevent counterfeit drug packaging. UV ink can be applied to drug labels to include invisible codes, while laser markings can be used for the permanent serialization of drug packaging.

5.2 Luxury Goods: High-end fashion brands and luxury goods often use laser anti-counterfeiting ink to engrave unique serial numbers or logos, ensuring that their products cannot be easily replicated.

5.3 Electronics: Laser engravings are commonly used for marking electronics, such as mobile phones and laptops, with unique identifiers that provide anti-forgery protection.

6. Conclusion: Making the Right Choice for Your Business

In the world of anti-forgery printing ink, both UV ink and laser ink provide distinct advantages depending on the security needs of your product. UV ink is perfect for high-volume, cost-effective applications that require invisible security marks. On the other hand, laser ink offers a permanent, tamper-proof solution. It is ideal for high-value, precision-based items, ensuring security and longevity.

At Mingbo, we specialize in providing both ultraviolet anti-counterfeiting ink and laser anti-counterfeiting ink tailored to your specific requirements. Whether you’re looking for a cost-effective solution or a high-security, permanent marking system, we offer custom anti-counterfeiting solutions to protect your brand from forgery.

Contact us today to learn more about our anti-forgery printing ink options and how we can help you secure your products against counterfeit threats.