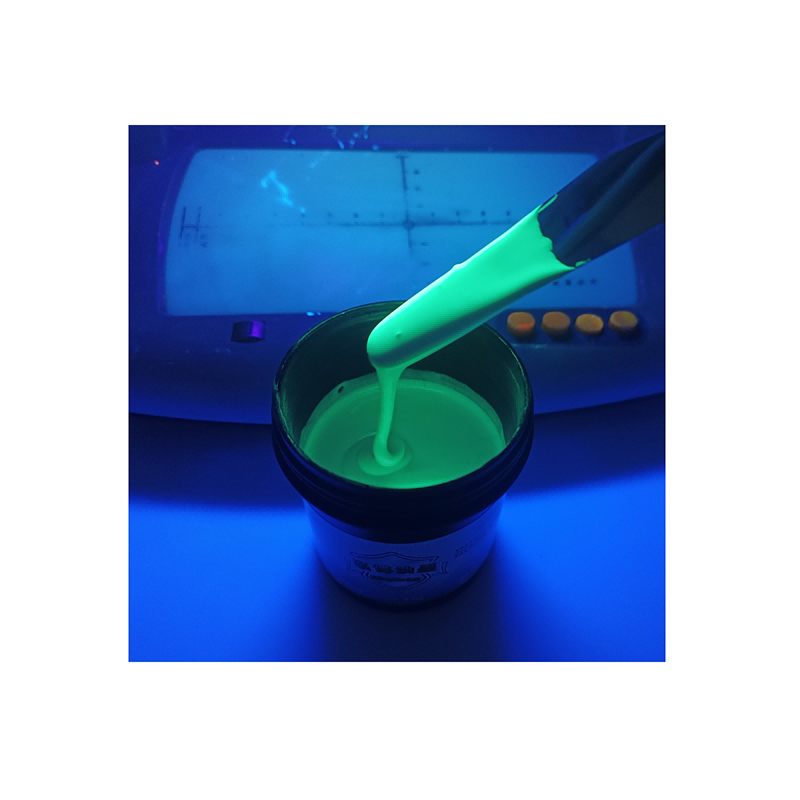

In screen printing, choosing the right ink is crucial for efficiently achieving high-quality results. One of the most advanced solutions available today is UV screen printing ink. This type of ink has gained significant popularity due to its numerous advantages, particularly its ability to enhance printing speed, reduce drying time, and improve color performance. In this article, we’ll explore how printing ink can take your printing projects to the next level.

1. Faster Drying Time: A Game Changer for Productivity

One of the key benefits of UV printing ink is its fast drying time. Traditional screen printing inks often require long drying periods, causing delays in the production process. UV screen printing ink, on the other hand, dries instantly when exposed to ultraviolet light. This means that the printed material is ready for further handling or processing almost immediately, speeding up the overall production time.

Faster Turnaround Times: The instant drying process allows printers to complete jobs more quickly, leading to faster turnaround times and the ability to handle larger volumes of work. This is particularly advantageous in high-demand industries where time is of the essence.

Improved Workflow Efficiency: Faster drying times mean less waiting for each layer to dry, leading to smoother, more efficient workflows. This helps reduce bottlenecks in the printing process, allowing for a continuous flow of production.

2. Superior Color Performance: Achieving Rich, Vibrant Prints

Another significant advantage of UV screen printing ink is its superior color performance. UV inks offer brighter, more vivid colors that are highly resistant to fading, even under exposure to sunlight. This makes UV ink particularly useful for printing on items that need to maintain their color integrity over time, such as outdoor signage, promotional materials, and packaging.

Consistent Color Quality: Unlike traditional inks, which can sometimes suffer from inconsistencies or color fading, UV screen printing ink delivers more reliable color results across different prints. This consistency ensures that every batch of prints meets the same high standards.

High Gloss Finish: UV ink typically results in a higher gloss finish compared to conventional screen printing inks. This adds an extra layer of appeal to printed materials, making them more eye-catching and professional in appearance.

3. Environmental Benefits: Reduced Emissions and Energy Consumption

While improving printing efficiency, UV screen printing ink also offers environmental benefits. Unlike solvent-based inks, UV inks contain fewer volatile organic compounds (VOCs), which are harmful to both the environment and human health. The reduction in VOC emissions makes printing ink a more eco-friendly option.

Energy Efficiency: Since UV inks cure instantly, they require less energy during the drying process, leading to energy savings in the long run. This makes UV screen printing ink a more sustainable choice for printing companies looking to reduce their carbon footprint.

Eco-Friendly Materials: Many manufacturers of UV screen printing inks also use eco-friendly raw materials, further enhancing the environmental benefits of UV printing.

4. Durability and Longevity: Resistant to Wear and Tear

The durability of prints produced with UV screen printing ink is another standout feature. UV inks create a tough, scratch-resistant surface that is less prone to fading or wear compared to prints made with conventional inks. This makes UV-printed items ideal for use in harsh environments or for products that require long-term durability.

Better for Outdoor Use: UV printing ink is highly resistant to UV radiation, which means it won’t degrade or lose its vibrancy when exposed to sunlight. This makes it a popular choice for outdoor signs, vehicle wraps, and other outdoor applications.

Scratch and Smudge Resistance: The hardened finish of UV ink makes it highly resistant to physical wear, ensuring that the printed designs remain intact and look fresh for a longer period.

5. Wide Range of Applications: Versatility Across Materials

UV screen printing ink is highly versatile and can be used on a wide range of materials, including plastics, metals, glass, wood, and fabrics. This makes it suitable for a variety of applications, from promotional products to custom packaging.

Packaging Solutions: UV screen printing ink is commonly used for printing on packaging materials. Its fast curing time ensures that packaging can be printed and quickly processed for assembly or distribution, providing an efficient solution for companies in the packaging industry.

Custom Merchandise: Whether it’s custom t-shirts, mugs, or corporate gifts, UV printing ink can be applied to a variety of substrates, making it ideal for personalized products that require vibrant, long-lasting designs.

6. Why Choose Mingbo for Your UV Screen Printing Ink Needs?

At Mingbo, we offer high-quality screen printing ink that can significantly improve your printing efficiency and output. Our inks are designed to deliver vibrant colors, faster drying times, and exceptional durability, ensuring your printed materials stand out in any application.

We provide custom solutions tailored to your specific printing needs, helping you achieve optimal results for a variety of projects. Whether you’re printing on packaging, promotional products, or outdoor signage, Mingbo’s UV screen printing ink is the ideal choice for achieving the highest quality prints with faster turnaround times.

Conclusion

Screen printing ink is a powerful tool for improving both printing speed and quality. Its fast-drying nature, superior color performance, and environmental benefits make it an excellent choice for businesses looking to enhance their printing processes. By choosing ink, you can improve your workflow, reduce costs, and create high-quality prints that last.

Choose Mingbo for your UV screen printing ink needs and experience the difference in quality and efficiency for your next project.